This section describes procedures for acceptance of manufactured or fabricated materials and products. This section also describes the types of materials that are considered manufactured materials and provides guidelines for sampling these materials.

Sampling and testing materials and products must be done in accordance with contract specifications. Sampling and testing are of equal importance for assuring materials and products meet acceptance specifications.

The contractor is responsible for notifying the resident engineer of the need for inspection and acceptance testing of manufactured materials and products by submitting Form CEM-3101, “Notice of Materials to Be Used,” early in the project. Refer to Section 6-202, “Responsibilities for Acceptance of Manufactured or Fabricated Materials and Products,” of this manual for details on completing and submitting this form.

The resident engineer needs to be knowledgeable about acceptance methods used for different manufactured or fabricated materials and products, including:

When field sampling of manufactured or fabricated materials or products is required, the resident engineer is responsible for the “chain of custody” for material and product acceptance samples. Material acceptance samples must be under the control of Caltrans from the sampling point to when the sample is tested. The chain of custody for material and product samples is an important part of the Caltrans quality assurance program.

The following describe the responsibilities for acceptance of manufactured or fabricated materials and products.

The contractor is responsible for providing materials that comply with the contract specifications. The contractor is responsible for the quality of materials and, if required by the specifications, must provide a notice of materials to be used, shop drawings, certificates of compliance, mill test reports, environmental product declarations, quality control plans, and quality control test results. The contractor must use materials from Authorized Materials Lists, provide fabricated materials from audited facilities, and use materials that comply with Buy America and specified Buy Clean California Act requirements.

The contractor is responsible for submitting Form CEM-3101, “Notice of Materials to Be Used,” to the resident engineer for all materials to be used on the project. The contractor must provide sufficient notification to the resident engineer on the source, location, and quantity of materials to be inspected and tested so that the work will not be delayed. Section 6, “Control of Materials,” of the Standard Specifications requires the contractor to list on Form CEM‑3101 all sources of materials and where these materials are available for inspection. Receiving this form in a timely manner is critical to the success of the materials management process.

Form CEM-3101, which includes detailed instructions, is available at:

The specifications require the contractor to submit a certificate of compliance for various materials before they are incorporated into the work. Section 6-2.03C, “Certificates of Compliance,” of the Standard Specifications states that when a certificate of compliance is required it must be:

The intent of the certificate of compliance is to communicate to Caltrans that the contractor has accepted the material and is confident that it complies with the contract specifications. The contractor is responsible for providing the certificate of compliance before incorporating material into the project. The certificate of compliance and any supporting documentation must accompany the material to the job site when materials are delivered.

Table 6-2.3, “Materials Accepted by Certificate of Compliance,” in Section 6-203C, “Materials Accepted on the Basis of a Certificate of Compliance,” of this manual provides a list of materials requiring a certificate of compliance, as well as any additional documents.

The specifications require the contractor to provide certified test reports along with the certificate of compliance for various materials. For steel, this test data is commonly known as a mill test report. A certified mill test report is required for each heat and must contain physical and chemical analysis of the material. The requirements for the mill test report vary depending on the section of the specifications the material falls under.

Section 6-1.04, “Buy America,” of the specifications provides detailed information on Buy America requirements. Refer to Section 3-604, “Buy America,” of this manual for additional information. The following are examples of acceptable language included in the certificate of compliance to verify Buy America compliance for steel and iron materials:

“All melting and manufacturing processes for the product occurred in U.S.”

“100 percent melted and manufactured in the U.S.A.”

The following is an example of acceptable language included in the certificate of compliance to verify Buy America compliance for construction materials, such as nonferrous metals, plastic- and polymer-based products, glass, lumber, or drywall:

“All production processes for the product occurred in U.S.”

Section 6-1.06, “Buy Clean California Act,” of the specifications provides detailed information on Buy Clean California Act requirements including environmental product declarations. Refer to Section 3-606, “Buy Clean California Act,” of this manual for additional information.

The Standard Specifications requires the contractor to submit shop drawings for review by Caltrans for certain structures such as structural steel and structural precast concrete. The shop drawings must include both shop details and erection plans. For more information on submittal and authorization of shop details and erection plans, refer to the Standard Specifications.

Contractors must submit shop drawings for overhead sign structures. For more information on submittal and authorization of shop drawings, refer to the Overhead Sign Structures Guide. Section 4-56, “Overhead Sign Structures, Standards, and Poles,” of this manual contains additional information.

Before Caltrans performs any source inspection, the contractor is required to have a copy of the authorized shop drawings at the location of inspection.

The Standard Specifications requires the contractor to submit a quality control plan for certain types of production. Information on quality control plans for those production types is provided in the Standard Specifications:

The resident engineer does not allow work to begin until the quality control plan is authorized for that production. For more information on the contents of quality control plans, refer to the Standard Specifications.

Specifications for welded products usually require the contractor to submit the fabricator’s welding quality control plan to the resident engineer for authorization before any products are manufactured for Caltrans. For details on quality control plans for welding, refer to Section 11, “Welding,” of Bridge Construction Records and Procedures Manual, Vol. 2:

The resident engineer must verify that materials entering the work comply with the requirements in the contract specifications.

The resident engineer must verify that the contractor submits Form CEM-3101, “Notice of Materials to Be Used,” for all materials. If the contractor does not submit Form CEM-3101 before the preconstruction conference, provide a list to the contractor during the preconstruction meeting of materials required to be listed on Form CEM-3101.

If the sources of all materials are not known, the contractor may submit a partial list of materials sources on Form CEM-3101 and submit Form CEM-3101 supplements as soon as other sources are known.

METS developed the J2 database for tracking project materials requirements, Form CEM-3101 processing, materials test results, and source inspection. Entering the contract number at the top of the database in the “Projects” box opens that project’s main page. Clicking on the “3101 Report” tab opens a list of all the bid items requiring Form CEM-3101 for the project and which Form CEM-3101s have been received. The list shows the name and address of the supplier and the date the Form CEM-3101 was received.

Assistance in developing a list of project materials that require Form CEM-3101 and in navigating the J2 database is available from the Materials Engineering and Testing Services (METS) representative for the project:

The contractor’s submitted Form CEM-3101 must include the following information:

Check Form CEM-3101 for the required information and for completeness. To make sure that all structural materials are listed, a list of materials necessary based on contract bid item is available at:

If the contractor’s Form CEM-3101 is incomplete or incorrect, require the contractor to complete the form. When the contractor’s Form CEM-3101 has been reviewed and is complete, promptly distribute Form CEM-3101 copies, including one to METS. The resident engineer sends Form CEM-3101 to the materials administrator using one of the following methods:

Materials Administrator, Mail Station #5

Materials Engineering and Testing Services

5900 Folsom Blvd, Room 517

Sacramento, CA 95819

METS will make required assignments for sampling, testing, and inspection of materials as noted in Section 6-202C, “Materials Engineering and Testing Services,” of this manual.

Based on assignment of materials inspection from METS to the resident engineer and the information shown on Form CEM-3101, the resident engineer must identify the appropriate district samplers, testers, and inspectors. Following is a partial list of those who may need to be notified to perform material acceptance:

Some structural materials such as structural precast concrete, overhead signs and poles, and steel pipe piling must be fabricated at a facility on the authorized facility audit list of fabricators who have successfully completed Caltrans’ facility audit. If these materials are included in the scope of work, make sure that the contractor is aware of these requirements. Information on the authorized facility audit list is available at:

The resident engineer must assure materials production plants meet specifications before they produce material for Caltrans. Request assistance from the district weights and measures coordinator for inspecting materials plants including:

Section 9-1.02, “Measurement,” of the Standard Specifications indicates the general requirements for weighing, measuring, or metering devices and the requirement to place security seals on material plant controllers. The district weights and measures coordinator will follow the MPQP and the contract specifications for material plant authorization.

The Materials Engineering and Testing Services (METS) assigns personnel for sampling, testing, and inspecting manufactured materials and products, usually at the source of supply. Manufactured materials and products shown in Table 6-2.3., “Materials Accepted by Certificate of Compliance,” in Section 6-203C, “Materials Accepted on the Basis of a Certificate of Compliance,” of this manual, are the responsibility of METS but have been delegated to the resident engineer for inspection.

METS assigns the responsibility for sampling, testing, and inspecting manufactured materials and products based on the information submitted on Form CEM-3101, "Notice of Materials to be Used." METS offices in Sacramento, the San Francisco Bay Area, or Los Angeles conduct most of the inspections. METS may assign sampling, testing, and inspecting of manufactured materials and products to the district materials engineer, resident engineer, or a commercial laboratory.

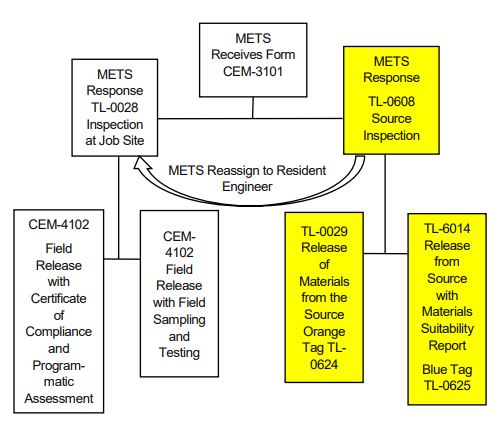

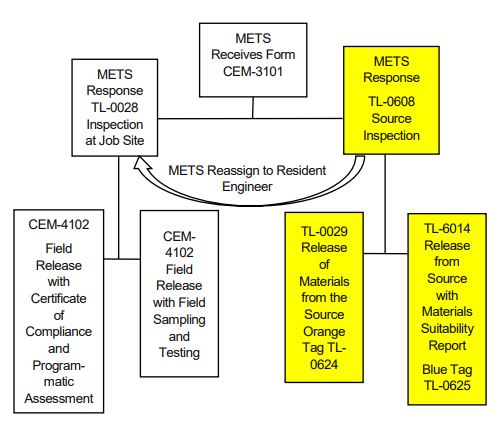

The METS process for inspecting and releasing manufactured or fabricated materials or products is shown in Figure 6-2.1., “Inspection and Release Flowchart—Source Inspection.”

Once Form CEM-3101 is received by the materials administrator, it is routed to the appropriate METS office for processing. Any questions regarding Form CEM-3101 processing by METS may be routed to the project METS representative. Structural materials listed on Form CEM-3101 are processed by the quality assurance and source inspection (QASI) office assigned to that project.

If it is determined that the material does not require source inspection, METS will assign inspection to the job site by completing Form TL-0028 for that material item. This form indicates that the material item does not require source inspection from Caltrans at this time. METS will send Form TL-0028 to the resident engineer, prime contractor, and suppliers to inform them that source inspection is not required before shipment to the job site.

The resident engineer will release these materials at the job site using Form CEM-4102, “Materials Inspected and Released on Job.” Section 6-3, “Field Tests,” of this manual contains details on testing that occurs at the job site. Depending on the material, the resident engineer bases the field material acceptance on various methods. Refer to Section 6-203D, “Field Inspection and Release by the Resident Engineer,” of this manual for the field inspection and release procedures.

If it is determined that the material requires source inspection before shipment to the job site, METS will issue Form TL-0608 to the resident engineer, contractor, and supplier. A hard copy of Form TL-0038, “Inspection Request,” is mailed with Form TL-0608 to the supplier. The inspection request form is to be used by the contractor or any subcontractors to inform METS when the material is ready for inspection.

Source inspection by Caltrans is described in Section 6-202C, “Materials Engineering and Testing Services,” of this manual and is detailed in the QASI Manual:

Form TL-0038 is used by the contractor or supplier to inform Caltrans that material located away from the job site is ready for inspection. If the contractor has received a Form TL-0608 for an item, Caltrans will be expecting a Form TL-0038 to initiate the source inspection.

Form TL-0038 and instructions for submitting the request are available at:

It is important to remind the contractor that, in accordance with Section 6-2.01E, “Material Source Inspection and Testing,” of the Standard Specifications, the inspection request must be submitted:

The resident engineer may also use Form TL-0038 to request field inspection by METS for structural items such as field welding.

METS may assign inspection of manufactured or fabricated materials and products for which they have acceptance responsibility back to the resident engineer. Refer to Section 6-203D, “Field Inspection and Release by the Resident Engineer,” of this manual for details on inspection and release.

The resident engineer must verify that materials entering the work meet the contract specifications acceptance criteria. Materials acceptance can be based on:

If the material delivered to the job site lacks proper identification, the report of inspection is unconfirmed, or the acceptability of the material is questionable, do not allow materials to be incorporated in the work until they have been found to comply with the specifications. Contact the assigned inspection unit to verify testing or submit samples for new acceptance tests.

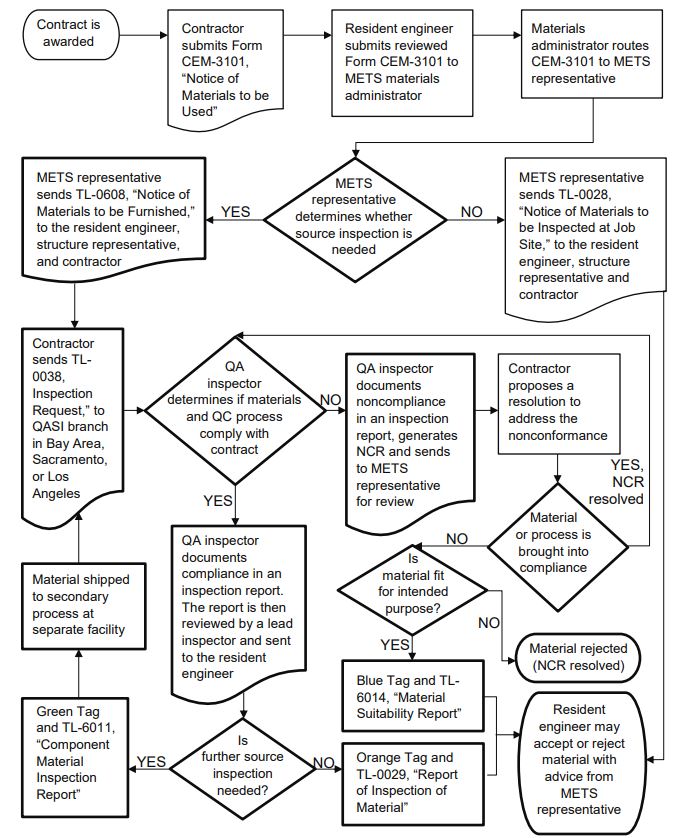

METS is responsible for the source inspection process shown in Figure 6-2.2., “Source Inspection Flowchart.” The flowchart includes information on what happens when a material is not in compliance with the specifications, prompting use of a TL-0015, “Quality Assurance Nonconformance Report.”

When a material listed on Form CEM-3101 is assigned a Form TL-0608, source inspection is required before the material to the job site. Table 6-2.1., “Inspection of Fabricated and Manufactured Materials,” provides a list of common materials on Caltrans projects and some of the primary source inspection activities. Table 6-2.1. follows Section 6-203A (5), “Source Inspected Materials Acceptance,” of this manual.

A METS inspector will travel to the source of the material and perform inspection, sampling, verification testing, and material release as necessary. Complex fabrication, such as with precast prestressed concrete members and structural steel, typically requires inspection during fabrication.

METS must receive all information that could affect materials that are source inspected. Forward all copies of authorized shop drawings as well as notification of approved change orders to the METS representative for the project. Forward to METS copies of approved shop drawings without established distributions, for example, buildings or small structures, and notification of approvals, such as paint color, or change orders. METS should receive copies of all correspondence with contractors or suppliers that may affect the fabrication.

Some inspections require out-of-state travel. It is important for METS to receive all documents before travel to assure timely inspection and release. For instance, light poles are manufactured at suppliers throughout the U.S.; therefore, it is crucial that authorized shop drawings are available for the METS inspector in time for inspection and release. The travel time for such inspections is significant. Coordination between resident engineer and METS is crucial for timely release of the poles.

In addition to source inspection, METS performs sampling and testing for certain materials for conformance with associated standards as a part of the quality assurance program. The list of additional tests performed by METS is available in detail in the QASI Manual.

The main point of contact for the resident engineer for anything related to source inspection is the METS representative assigned to the project. A list of METS representatives is available at:

The contractor is responsible for submitting Form TL-0038, “Inspection Request,” to the appropriate METS QASI office with sufficient notice as described in Section 6-2.01E, “Material Source Inspection and Testing,” of the Standard Specifications. The appropriate office to send Form TL-0038 is available on the METS website:

This website allows the contractor to determine the appropriate QASI office by district. The TL-0038 can come from the contractor or subcontractors.

Each QASI office has a dispatcher who receives Forms TL-0038 and schedules inspections.

The METS representative assists the resident engineer with management of source-inspected materials. The METS inspector acts as the eyes and ears of the METS representative and resident engineer at the material’s source. Inspected materials are identified with a unique inspector lot number that correlates the material with reports and release tags.

The METS inspector assesses the source’s quality control methods and reviews the certificates of compliance and any additional documentation such as mill test reports. The METS inspector also performs random visual inspection of the material and any other required inspections such as nondestructive testing. For more information on the types of inspection required for common materials, refer to Table 6-2.1., “Inspection of Fabricated and Manufactured Materials,” of this manual and the QASI Manual.

If sampling of the material is required at the source, the METS inspector will randomly sample the material at the required frequency and fill out a TL-0101, “Sample Identification Card,” to accompany the material to the Transportation Laboratory. Sampling may be performed in the field by either the METS inspector or field construction staff. The material’s certificate of compliance and any additional documents must be sent with the material to the lab as well. If the material is undergoing mechanical testing, the resident engineer can track the testing progress by using the J2 database and clicking on the “SMTL Test Reports” tab for the project.

If the material is found to be acceptable, the inspector identifies it with Form TL-0624, “Inspection Release Tag,” commonly known as an orange tag. METS inspectors will not necessarily tag every bundle and piece in a shipment. If there are many components going out in one shipment, it is common that a single orange tag will be placed on the load. The orange tag will correlate to the certificate of compliance and bill of materials with the inspector’s unique lot number. This tells the resident engineer what material the tag covers.

After the material is orange-tagged for release, the METS inspector enters the lot number, a description, and quantity of materials inspected on Form TL-0029, “Report of Inspection of Material.” A completed copy of Form TL-0029 is sent to the resident engineer for the project records.

Certain materials are included in the METS authorization-to-deliver program. Source inspection for these materials is different from typical procedures in that it includes a recurring audit at a prescribed frequency, with material sampling and testing. If the facility is approved to be in the authorization-to-deliver program, it is authorized to ship material to the job site without receiving a physical tag for the material. A TL-0029AD, “Report of Inspection of Material (Authorization to Deliver),” is produced by METS and sent to the resident engineer and the supplier notifying them that the material is acceptable to be shipped. The resident engineer should not expect to obtain a tag from the material if a TL-0029AD report was received. However, the resident engineer should match the TL-0029AD report with the actual shipped material quantities and certificate of compliance to verify that the material arrives within a reasonable timeframe.

When source-inspected materials arrive on the job site, the attached Form TL‑0624 informs the resident engineer to permit use of the materials. The attached form shows the identifying lot number, the inspector’s initials, and the date of inspection. If the item does not lend itself to attaching of tags, such as reinforced concrete pipe, the inspector marks the lot number on each separate piece. In some instances, when there is a possibility of losing tags, the inspector both attaches tags and marks a lot number on the pieces. METS inspectors will not necessarily tag every bundle and piece in a shipment, with the exception of reinforced concrete pipe.

It is important to note that the resident engineer must inspect the materials for damage that may have occurred during shipping or storage and for general quality of work and conformance to planned shape or dimensions. Table 6-2.1., “Inspection of Fabricated and Manufactured Materials,” of this manual provides examples of types of field inspections for common materials.

The resident engineer may not receive the completed Form TL-0029, “Report of Inspection of Material,” until after the materials have arrived at the job site. The resident engineer must check that the correct material was shipped to the job site by verifying that the lot number and quantity of material shown on Form TL-0029 matches the identifying information, such as Form TL-0624, that was attached to or marked on the materials. Notify the project METS representative of any discrepancies so that an investigation can be conducted.

The resident engineer must inform the assigned METS inspection office if Form TL‑0029 is not received within 15 days after receipt of materials.

For inspections made during fabrication, METS will produce an inspection report, unique to the type of inspection, and distribute it to the resident engineer for review and incorporation into the project files. More information on the various types of inspection reports is in the QASI Manual.

If the inspector observes that the material does not comply with the specifications at the requested time of release, the manufacturer or fabricator is notified and allowed one work shift to correct. If the material cannot be brought into conformance within the time period, METS will send a TL-0015, “Quality Assurance Nonconformance Report,” (NCR) to the resident engineer within 24 hours of the observation. The resident engineer then notifies, in writing, the contractor of the NCR and requests a written response to resolve the issue.

The purpose of the NCR is to formally document the reason the material does not meet the specifications and to prompt the contractor to propose resolution and prevention measures in the response letter. This report is entered into the J2 database under the “Issues” tab so that the information is available to Caltrans staff outside the project to help avoid future issues statewide.

When the resolution letter is submitted by the contractor, the resident engineer and METS will perform a review. If the resolution is insufficient, the contractor will be notified and allowed to revise the letter and resubmit. If the resident engineer decides that the material is not suitable for the project, it will be rejected and prohibited from incorporation into the project.

If the letter is found to be acceptable, METS will issue a TL-0016, “Quality Assurance‑Nonconformance Resolution,” to the resident engineer recommending a resolution and closure of the issue. In some cases, the material is found to be suitable for the intended purpose by the resident engineer, METS, and the engineer of record for project design, but it does not meet the contract specifications. In this case, METS will produce a TL-6013, “Material Suitability Documentation Report,” to document the engineering judgment used to determine the material to be suitable and concurrence from the resident engineer, METS, and engineer of record for project design. Once authorized, the material can be released by the inspector by placing a TL-0625, “Material Suitability Tag,” referred to as a blue tag onto the material in a similar fashion as with an orange tag. A TL-6014, “Material Suitability Report,” is written in place of a TL-0029, “Report of Inspection of Materials,” and sent to the resident engineer.

Because of costs incurred by Caltrans when traveling for source inspection to material sources that are far from the job site, Section 6-2.01E, “Material Source Inspection and Testing,” of the Standard Specifications provides the details for deductions to be taken when applicable. To determine where inspections have taken place for a project, the resident engineer can review the inspection reports that provide inspection locations.

The resident engineer and METS share the responsibility for inspection of materials at the source. The resident engineer has the sole responsibility for acceptance of material and may determine that materials are not acceptable for a project based on any of the following reasons:

Another situation not controllable by inspection at the source is the transfer of materials from one contract to another. The inspector can confirm in the original inspection report that a given amount of material with a given lot number was inspected for the first contract. Identifying the material as that received on the first job under the original inspection report and monitoring its transfer from one job to another are responsibilities of the resident engineers involved. Such transfers should not be allowed unless the material is positively identified or is of a type, such as fencing or reinforcing steel, that can be resampled and retested in the event identification is lost or is questionable.

Table 6-2.1., "Inspection of Fabricated and Manufactured Materials," lists manufactured or fabricated materials and products that are usually inspected at the site of manufacture or fabrication and indicates items that are checked by the inspector at the source. Table 6-2.1. also includes items that must be checked or rechecked at the job site to assure that the materials are acceptable. The table does not cover all manufactured or fabricated materials and products but provides typical examples. Verification at the source of fabrication does not preclude acceptance by the resident engineer at the job site. For more details on the inspection procedures, refer to Section 6-3, “Field Tests,” of this manual, and the QASI Manual.

The specifications require that certain products be manufactured to state specifications. Occasionally, composition of the specified formulation is changed and the newer specification results in an equal or better product. Materials manufactured under specifications newer than those that apply to a particular project are acceptable for use. METS inspectors release such materials, and resident engineers may permit use of such materials without change orders unless specifically advised to the contrary. State specification numbers for manufacturer materials are shown in the Standard Specifications or special provisions.

Paint manufactured under state specifications is sampled at the factory, tested by METS, and identified by lot numbers before shipment to the project.

Product

Items Inspected and Tested by METS

Items to Check at Job Site

Bolts, nuts, and washers

Material sampling and testing including galvanizing, visual inspection.

Visible defects, dimensions, threads, galvanizing, marking for correct type fit of nuts. Make sure high-strength bolts and nuts are used where specified and nuts are lubricated properly. Refer to Bridge Construction Records and Procedures.

Curing compound, chlorinated rubber type

Material tests by batch or lot, check marking. Other types accepted at job site if properly packaged and labeled.

Proper mixing, marking, check sample. Check for specified type of container and correct marking.

Bearing, elastomeric bearing pads - steel reinforced, PTFE bearing

Material sampling and specified tests, visual and dimensional inspection certification.

Damage, defects, uniformity, dimensions.

Electrical items: controllers, luminaires, signal heads, conductors

Controllers: complete tests and inspection.

Luminaires: random tests, visual inspection.

Signal heads, switches; visual inspection plans, type, operational check.

Conductors: random tests.

Shipping damage, defects, conformance to plans, type, operational check. Check loop detectors for operation under field conditions inspection. See that all conductors are correct type and size.

Materials sampling and specified tests, markings, packaging.

Proper material for intended use, excessive thickening or crystallization, proper mixing.

METS inspection and tests upon request from resident engineer. Material tests, visual and dimensional inspection.

Size, uniformity, surface defects, warping (permit no repairs).

Girders, precast prestressed concrete

Material verification, work quality, dimensions, conformance to plans, and in-process inspection of fabrication such as for forms, steel placement, stressing, and concrete stages.

Damage, flaws, exposed steel dimensions, finish, cracks, or other defects.

Product

Items Inspected and Tested by METS

Items to Check at Job Site

Girders, structural steel

Material verification, check sample testing, qualifications of welders, inspection during fabrication, nondestructive testing, preparation and painting in the shop, conformance to plans and authorized shop drawings, proper joint preparation for shop-bolted connections.

Damage to members or paint: defects in steel, camber condition of paint, dimensions, condition of holes, straightness and squareness of members.

Joint sealant, Type A field mixed polyurethane or silicone sealant

Material sampling and testing by batch or lot.

Proper components, proper mixing, marking. Damage, work quality, correct movement range from test report, size and type, lot and batch identification. Refer to Bridge Construction Records and Procedures.

Joint seal, Type B preformed elastomeric joint seal

Material sampling and testing.

Damage, work quality, correct movement range (from test report), size and type.

Tests of each batch or lot, random inspection.

Damage, surface defects.

Mechanical equipment, scales, pump truck inspection stations, roadside rests

Inspection usually assigned to resident engineer. Consult with Structures & Engineering Services, Office of Electrical, Mechanical, Water and Wastewater Engineering, for assistance if required.

Damage, installation details, work quality.

Product

Items Inspected and Tested by METS

Items to Check at Job Site

Metal beam guard rail

METS inspection and testing of galvanizing upon request by resident engineer.

Damage to rail or galvanizing, flaws of rail and galvanizing, dimensions, conditions of holes, for example.

Metal crib wall

METS inspection and testing of galvanizing upon request by resident engineer.

Dimensions, work quality, galvanizing, specified bolts.

Miscellaneous iron and steel, miscellaneous bridge metal, bearing assemblies, rings and covers, frames and grates

Materials sampling and testing as specified, qualification of welders, inspection of fabrication, galvanizing, dimensions.

Damage, welding or fabrication defects, conformance to drawings, galvanizing defects, grinding specified coating.

Materials sampling and testing by batch or lot.

Lumps, hard setting, color, marking of cans, adherence, surface preparation, lot numbers (same as on inspection report).

Piling, precast prestressed concrete

Material verification, work quality, dimensions, conformance to plans, and in-process inspection of fabrication, such as forms, steel placement, stressing, and concrete stages.

Damage, flaws, such as cracks, and spalling, painting of strand ends, straightness.

Piling, steel pipe

Material verification, weld inspection of welding if field splices are necessary.

Damage to members, overlooked fabrication details, dimensions.

Material sampling and testing. Check galvanizing thickness.

Size, uniformity, surface defects; permit no repairs.

Material verification, inspection and review of welding and galvanizing, visual and dimensional inspection.

Dimensions, welds, work quality, galvanizing type.

Product

Items Inspected and Tested by METS

Items to Check at Job Site

Material sampling and testing, package and storage, visual inspection when possible.

Check strand for rust, damage, surface defects. Check tags for stressing information.

Reinforced concrete pipe

Material verification, witness testing, visual inspection, dimensions, elliptical steel markings. Only for reinforced concrete pipe with diameter greater than 60 inches, unless requested by resident engineer.

Damage, defects, exposed steel, dimensions at specific locations in accordance with plans, straightness, concentricity.

Bridge railing, barrier

Material tests, welder qualifications, welding and fabrication, galvanizing.

Damage to rail or galvanizing; fabrication or galvanizing defect, fit of sleeves, dimensions; types of bolts or nuts furnished.

Reinforcement splices: welded or mechanical couplers

METS sampling and testing, material verification.

Refer to Bridge Construction Records and Procedures.

Material verification, qualification of welders, inspection during and after fabrication, dimensions, cleaning and painting or galvanizing.

Damage, general work quality, general conformance to requirements, position of sign panels, final check of electrical equipment for illuminated signs, proper nuts and bolts, properly torqued.

Signs, changeable message

Fabrication, operation, work quality.

Refer to Section 4-56, “Overhead Sign Structures, Standards, and Poles” of this manual.

Product

Items Inspected and Tested by METS

Items to Check at Job Site

Steel flooring and grating

METS inspection and tests upon request from resident engineer.

Work quality, dimensions.

Material verification, qualifications of welders, inspection during fabrication, nondestructive testing, preparation and painting in the shop, conformance to plans and authorized shop drawings, proper joint preparation for shop-bolted connections.

Damage to members or paint: defects in steel or in welds; overlooked fabrication details; camber condition of paint; dimensions; condition of holes; proper bolts and nut markings; proper torquing; straightness and squareness of members.

The specifications identify materials that must be on an Authorized Materials List. The list is available at:

The engineer must make sure materials or products listed in Table 6-2.2., “Materials Acceptance Based on Authorized Material Lists,” are shown on the appropriate Authorized Materials List before the material is used on the project. Materials shown on the Authorized Materials List may also require a certificate of compliance or sampling and testing for acceptance.

Material or Product

Authorized Materials List

Alternative sound wall system

Signing and delineation materials

Drilling and bonding dowels

Chemical adhesives or cartridge epoxies

Flexible pavement crack treatment material

Chemical admixtures for concrete

Innocuous aggregates for concrete

Concrete anchorage devices

Corrosion protection system

Corrosion protective coverings

Corrosion protection covering for splices

Corrosion protective coverings

Signing and delineation materials

Detectable warning surface

Detectable warning surface

Earth retaining system

Earth retaining systems

Battery backup external cabinet

External battery backup system cabinet

LED signal modules

LED traffic signals

Fusion-bonded epoxy powder

Signing and delineation materials

Steel reinforcing couplers

Organic zinc-rich primer

Organic zinc-rich primer list

Signing and delineation materials

Pavement traffic stripe and marking tape

Signing and delineation materials

Material or Product

Authorized Materials List

Post-tensioning prestressing system

Pre-approved systems; full list and details

Precast portland-cement-based repair material

Precast portland-cement-based repair material

Signing and delineation materials

Headed bar reinforcement

· Retroreflective sheeting for barricades

· Retroreflective bands for portable delineators

· Retroreflective sheeting for construction area signs

· Retroreflective sheeting for channelizers

· Reflectors for Type K temporary railing

· Retroreflective cone sleeves

· White and orange-colored retroreflective stripes for plastic traffic drums

· Portable signs Type VI, retroreflective, elastomeric roll-up fabric

Signing and delineation materials

Signing and delineation materials

Fiberglass-reinforced plastic panels

Signing and delineation materials

Silane reactive penetrating sealers

Temporary crash cushion

Highway safety features

Material or Product

Authorized Material List

Temporary traffic control devices

Acceptable, crashworthy Category 2 hardware for work zones

Temporary traffic control devices

Highway safety features

Thread locking systems

Anaerobic thread locking systems

Undercoating for ungalvanized sign structures

Warm mix asphalt

Warm mix asphalt—approved technologies

In accordance with Section 6-2.03C, “Certificates of Compliance,” of the Standard Specifications, the engineer may permit the use of certain materials before sampling and testing if accompanied by a certificate of compliance.

Acceptance based on certificates of compliance is used for products for which the industry has demonstrated a high degree of reliability in meeting specifications. METS performs a programmatic assessment on a periodic basis of materials that do not receive source inspection.

METS notifies the resident engineer when material from any producer is not acceptable on the basis of a certificate of compliance. The resident engineer must notify the contractor when material cannot be accepted based on a certificate of compliance and require submittal of samples for testing before use on the project.

Certificates of compliance should contain the following information:

Materials accepted based on a certificate of compliance arrive on the job site without inspection by METS and Form TL-0029, “Report of Inspection of Material.” When required by the Standard Specifications or the special provisions, verify that these materials have a certificate of compliance and any required additional backup documentation, such as mill test reports for steel, pressure treating reports for timber, and concrete test reports, to show that the materials comply with the specifications. Table 6-2.3., “Materials Accepted by Certificate of Compliance,” shows materials in the Standard Specifications that are accepted based on a certificate of compliance.

In addition to the materials listed in Table 6-2.3., in accordance with Section 6-2.03C, “Certificates of Compliance,” of the Standard Specifications, a certificate of compliance is required for material produced outside the United States.

Contact the project METS representative regarding any feedback or additional detail for programmatic assessment or systematic concerns regarding certain materials types.

When material delivered with a certificate of compliance is improperly certified, or any part of it is found not to comply with specifications, reject the entire shipment and notify METS immediately.

Procedures for sampling and testing materials accepted by certificate of compliance vary depending on the material. Following are some details covering the sampling of materials accepted by certificate of compliance.

Material/Product

Remarks (Including Requirements for Additional Backup Information Required with Certificate of Compliance)

Alternative earth retaining systems

Must state that the supplied material complies with the index criteria for the system at the time of prequalification.

Certificates of compliance must include the following:

I hereby certify by my signature that I have the authority to represent the supplier providing the accompanying asphalt product."

Certificate of compliance must include the following:

Asbestos cement pipe

Asbestos sheet packing

Test results required with each truckload.

Asphalt rubber joint sealant

A certified test report of the results for the required tests performed within 12 months before the proposed use.

Must include manufacturer’s statement of compatibility with the joint sealant to be used.

Material/Product

Remarks (Including Requirements for Additional Backup Information Required with Certificate of Compliance)

Blast cleaning material

Bonding agent for repairing spalled surface area

Submittal of certificate of compliance required for contracts of less than 60 working days.

Certificate of compliance must be submitted with a copy of each required test report.

Cast iron maintenance access rings and covers

Chemical adhesive for bonding tie bars and dowel bars in concrete pavement

Chemical adhesive for structures

Certificate of compliance must state compliance with ICBO AC58 and Caltrans. Augmentation/Revisions to ICBO AC58.

Certificate of compliance from the manufacturer must certify that the admixture furnished is the same as that previously authorized for the Authorized Material List.

Certificate of compliance must include the source name and location.

If the cementitious material is delivered directly to the job site, the certificate of compliance must be signed by the cementitious material supplier.

If the cementitious material is used in ready-mixed concrete, the certificate of compliance must be signed by the concrete manufacturer.

If blended cement is used, the certificate of compliance must include a statement signed by the blended cement supplier that shows the actual percentage of supplementary cementitious material, by weight, in the blend.

Certificate of compliance must include:

Material/Product

Remarks (Including Requirements for Additional Backup Information Required with Certificate of Compliance)

Before placing minor concrete from a source not previously used on the contract, a certificate of compliance stating that the minor concrete to be furnished complies with the contract requirements, including the specified minimum cementitious material content.

Chain link fencing and railing

Certificate required for protective coating system.

Concrete anchorage devices

Circular reinforced direct design method, less than 60 inches in diameter

Certificate of compliance must:

Corrugated metal pipe

Certificate of compliance must include:

Crumb rubber modifier

Test results required with each truckload.

Certificate of compliance required for:

Material/Product

Remarks (Including Requirements for Additional Backup Information Required with Certificate of Compliance)

Dowel bar baskets

Drop inlet grates and frames

Drip irrigation line

Elastomeric bearing pads

Certified test results for the elastomer.

METS samples and tests bearing pads.

Elastomeric bearing pads

Certified test results.

METS samples and tests bearing pads.

Battery backup system

Certificates of compliance are required for:

Conduit (galvanized and plastic)